Why

Vistaliner!? Why? (page two)

- Erick Cantu (12.22.04)

Continued from page one...

This left deciding who to release it with. I

didn't want SGA to have to support the model and Kittyhawk has its own problems, so we

created a fake group name which pays homage to my favourite train (the California Zephyr,

famous for its Vista-domed cars. Each car in the Zephyr pool was named, with the name

following the word 'Silver'), and that was that.

The first item of importance on the newly christened

SilverJet 727 was the wing. The 727s wing is an immensely difficult wing to get right (and

at the time only CS really did a good job of it), mostly for two reasons, the flaps, and

the elegant curve of the inboard leading edge. On the original FFX 727, the inboard wing

was a straight line, lacking this complex curve, which meant that the Krueger flaps were

ultimately shaped wrong. We made sure to not make the same mistake on this model, as so

many others did. This was thus one of the model's focal points, and a great deal of time

was spent on it. The flaps on the 727 present their own set of challenges, not only

because they are triple slotted, but also because the easiest way to get the animation

right was to model every last operating mechanism. This meant that the rails, shuttles,

screwjacks, and anything else had to be there, not only for animation but because it makes

little sense to have flaps floating on nothing! Another common mistake on 727 models was

the shaping of the bullet fairings on the flaps. These bullet fairings are where the flap

screws attach to the side of the flap, just behind the notches cut into the sides of the

primary (middle) section. It was decided that a couple of tubes attached to the flaps

wasn't going to do it, so they were built right into the flaps from separate parts,

individually shaped and blended (people who know me know the technique I used to do this,

it's the same way I do wingroots), joined, refined, re-smoothed, and tweaked to final

shape.

The result is what I'm not ashamed to say are what I

believe are the most accurate, if not the most detailed, 727 flaps in existence. I don't

like to brag (trust me, I have problems accepting accolades, I'd rather just do away with

them), and so you know I mean it from the bottom of my cold black heart. The leading edge

devices were another story in themselves, requiring loads of cuts, linkages, animations,

rails, proper sequencing, and so on. They're the first 727 LEDs to have every last rail

and piston animated, to the best of our knowledge, and in my opinion it was a miracle that

I didn't mess them up! Ailerons were then cut, as were spoilers, and light lenses. Fuel

dump pipes were added as well as logo light pods, static vanes, and lots of details I bet

you people don't even know are there! In addition to this, we wanted the wing to flex,

meaning it had to be cut just right to maintain a balance of functionality and smooth

flex. It was ultimately flexed in 3 places at the trailing edge and 4 at the leading edge,

providing a very nice, smooth, subtle flex. let's hope I never have to make another 727

wing again!

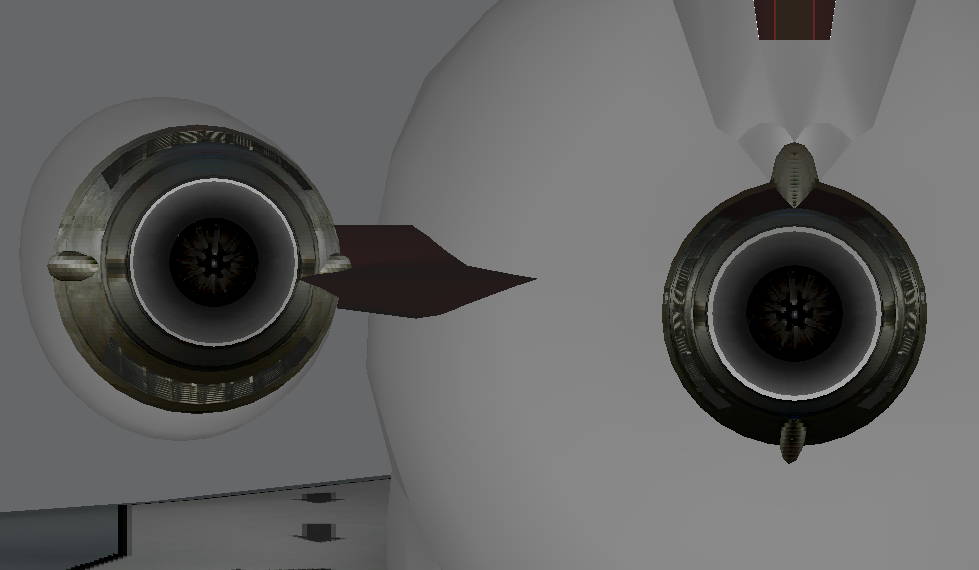

Engines were fairly straightforward (after making 4 or 5

sets of JT8Ds, it gets to be pretty routine to animate and texture a new one), as was the

texturing of the fuselage - we decided to use the tried and true one-piece fuselage and

tail, because it is popular with painters, and it's easier to work with. The next big

challenge was the landing gears. The nose gear was not too bad (you would be amazed how

similar the 727 and 737 nosegears are, but with the 60% airframe compatibility between the

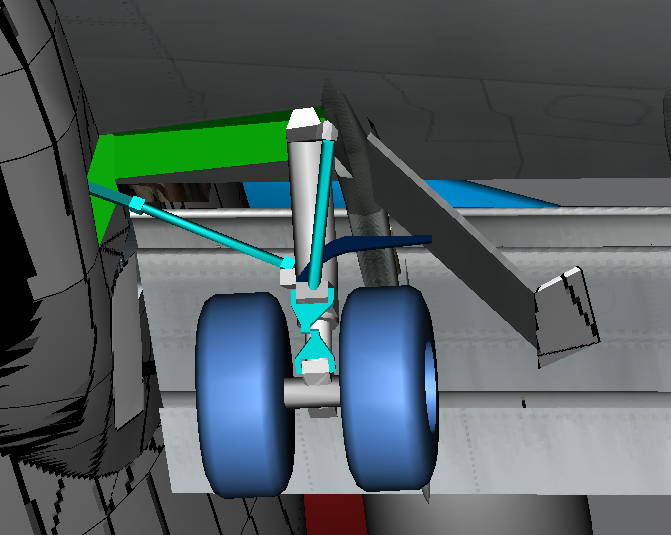

737 and 727, it should not surprise anyone!), however, the mains were a nightmare. We

decided to model them just like the wings - everything must move, including the break in

the upper gear strut (to our knowledge, again, something never done before). Thankfully,

this went a bit faster than the wings did, and within a couple of days we had a fully

functioning set of 727 main gears, from the sway brace to the strut break, everything was

present, and I was glad to be done with it! Gearbays followed, and once again Chris proved

to be indispensable as we had photos of every last area of the gearbays, and enough

materials to accurately model the APU as well! Thanks, Chris!

Finishing work was aerials, airstairs, lights, and the

cargo bay. It didn't take long, and we had a brand new 727 model to play with. Frit got to

work on his 'simple' FDE (which, incidentally, DOES fly by all published numbers and in

the opinion of the 727 pilots who flew it, was more than acceptable and certainly better

than 'simple!'), and the painters got to work.

...previous

continued...

Review home page

2

|

Vistaliner exhaust

Vistaliner gear-bay |